| Sizes |

DN15 to DN600 ( NPS 1/2 to NPS 24) |

| Pressure Rating |

Class 150, 300, 600, 900, 1500 & 2500 |

| Material Construction |

Cast Carbon Steel – WCB, WCC, etc.

Low Carbon Steel – LCB, LCC, etc.

Martensitic Steel – WC1, WC6, WC9, C5, C12, CA15, etc.

Austenitic Stainless Steel – CF8, CF8M, CF3, CF3M, CN7M, CG3M, etc.

Duplex Stainless Steel – CD4MCuN, CD3Mn, etc.

Nickel-Copper Alloy – Monel 400,

Nickel-Copper- Aluminium Alloy – Monel 500,

Ductile Iron – Grey Cast Iron, S.G. Iron, etc. |

| Design & Manufacturing Standard |

BS 1868, API 594, API 6D, DIN 3230 |

| Face to Face Std. |

ASME B16.10 |

| End Connection Std. |

ASME B16.5 |

| Testing Standard |

API 598 |

| Type of Bore |

Standard (Full Bore) |

| End Connection Type |

Flanged Ends, Screwed Ends, Socket Weld Ends, Butt Weld Ends, Victaulic Ends, etc. |

| Operated Type |

Self Operated |

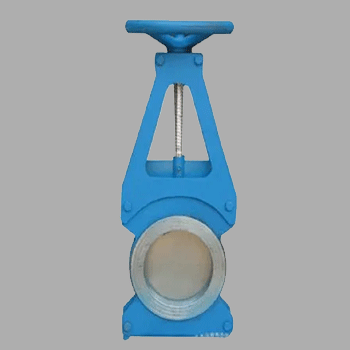

| Types of Check Valves or Non Return Valves |

Swing Check Valve, Dual Disc Check Valve, Single Disc Check Valve, Flap Type Wafer Check Valve, etc. |

|